turbocharger installation

follow our advice

The turbocharger is a very delicate and sophisticated mechanism, one that is unlikely to fail on its own, except after very many miles.

There are several factors that lead to turbo failure.

Following are some tips that will be of help to those installing the turbocharger.

01 The causes

The presence of foreign objects, lack of lubrication, oil contamination, excessive acceleration and excessive temperature are the main causes of turbocharger failure.

02 Preliminary verifications

Before installation, check that all connected air sleeves are perfectly clean and undamaged and that there is no residue of any kind inside.

Check the entire lubrication system.

Clean oil pan , clean or replace oil heat exchanger, oil suction system, oil pump.

Checking oil flow and pressure in both cold and warm engine, cleaning or replacing EGR, FAP, catalytic converter, MAF

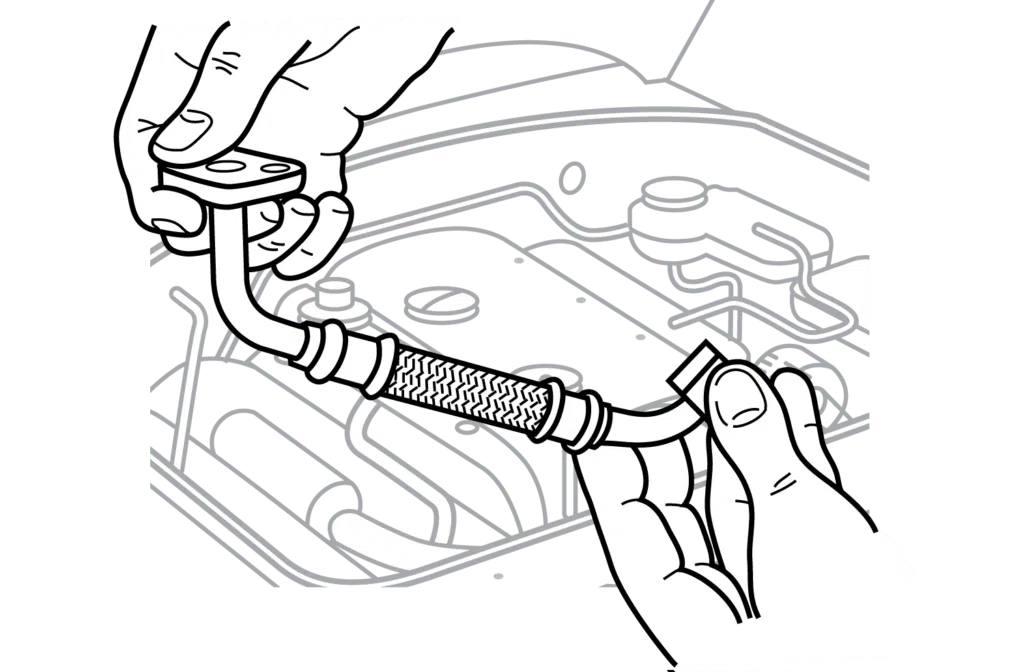

03 Gaskets

Be sure to use the correct gaskets.

Important: Do not use liquid sealants or gaskets, particularly for the oil inlet or outlet, as excess of such materials in the turbocharger could reduce or interrupt oil flow.

04 Oil change

05 Engine vent cleaning

Clean the engine vent system (positive crankcase ventilation system) and check its proper operation.

Any blockage or malfunction can cause high crankcase pressure and result in oil leakage from the turbocharger into the inlet and exhaust systems.

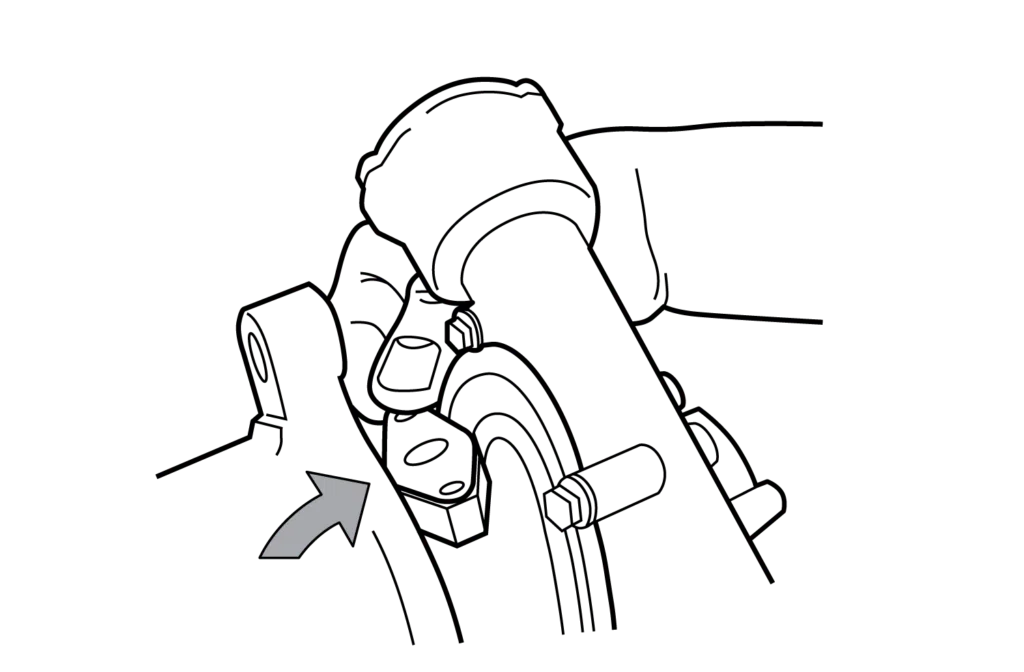

06 Drainage pipes

Pay special attention to the oil drainage and delivery pipes, which must be perfectly clean and free of damage to ensure unrestricted oil flow.

It is advisable to use a new oil inlet pipe when installing the turbocharger.

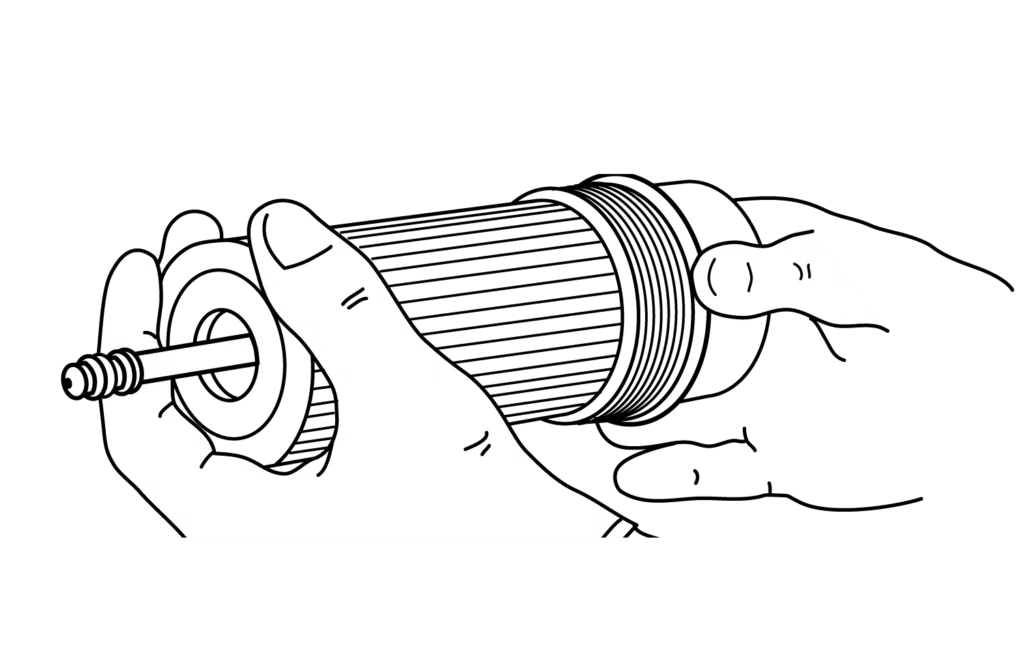

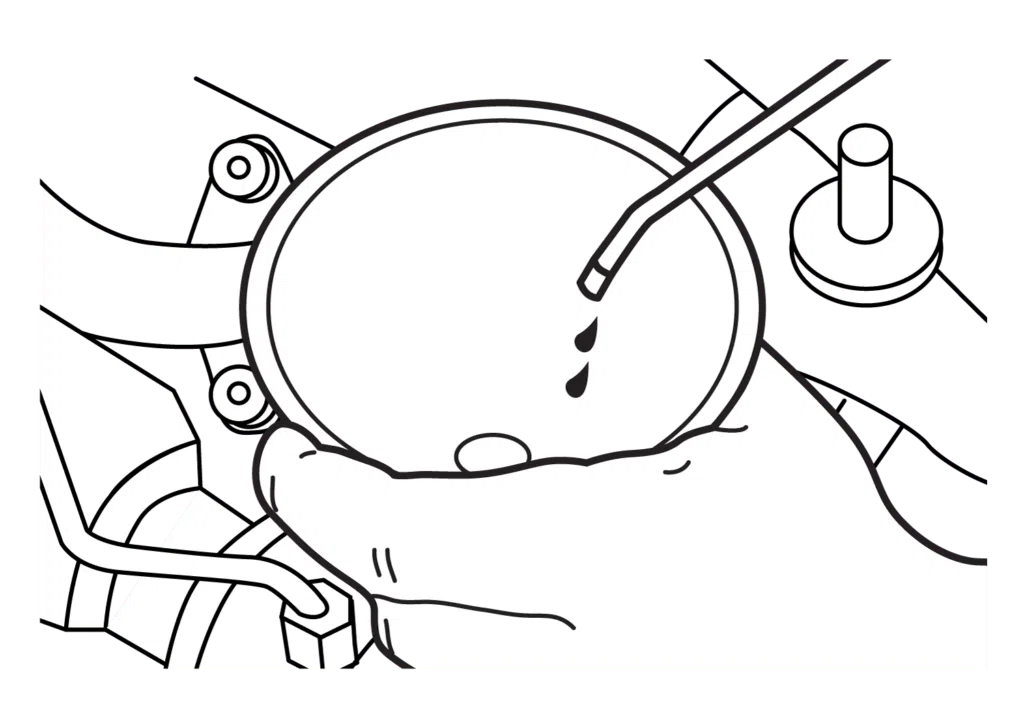

07 New oil

Pour the new engine oil into the turbocharger oil inlet hole.

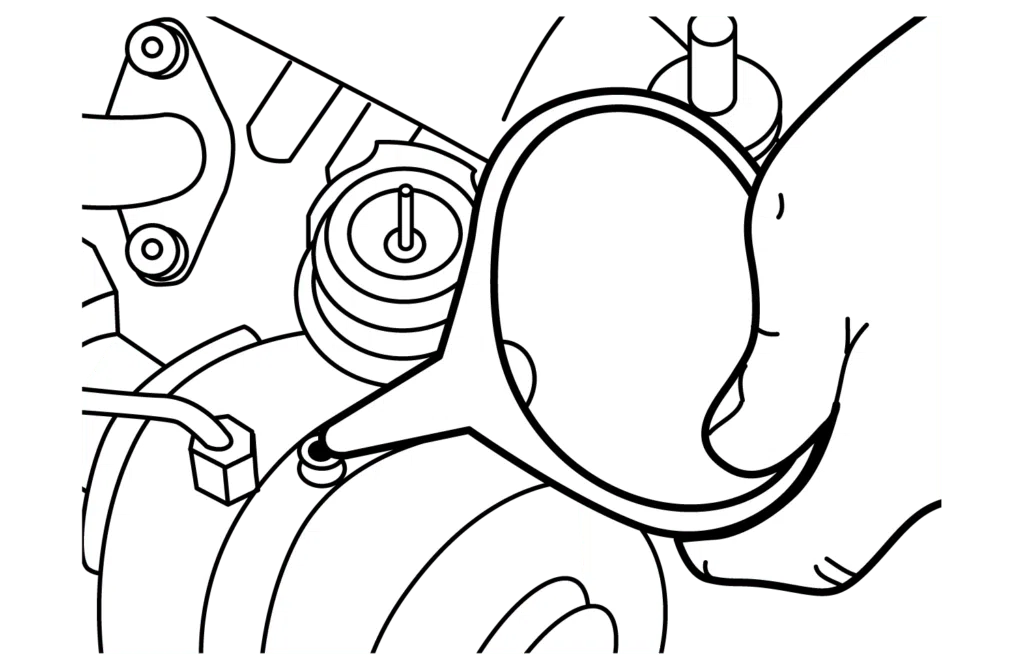

08 Engine start

Run the engine for 10-15 seconds without turning it on: turn off the power/injection or use the compression test mode.

This triggers oil flow to the turbocharger by filling the oil pressure hoses, oil filter, and turbocharger with oil before ignition.

Important: When starting the engine, the turbocharger runs at high speed, and failure to lubricate during these first important seconds could seriously affect the efficiency and durability of the new turbocharger.

09 Verifications

Start the engine and let it idle for 3-4 minutes to allow proper verification of oil, gas and air leaks.

If a leak is detected in the process of starting the engine, fix the problem immediately.

Turn off the engine and check the engine oil level again.